Table of contents

Orafol ORALITE reflective films – An overview: Film structure, differences & Application areas

The reflective film types from Orafol

Differentiation of Orafol reflective films according to performance classes and application areas

The microprismatic Orafol ORALITE film types

Further information on Orafol ORALITE films

Orafol® ORALITE® reflective films - An overview: Film structure, differences & areas of application

There are reflective materials with glass bead technology and reflective films that are made up of microprisms. In the case of microprismatic films, there are also differences in the appearance and arrangement of the individual reflective elements, which influences the reflective power, luminance etc. of the reflective films. This results in different areas of application and fields of use.

This article will focus primarily on microprismatic films (Structure C). Firstly, a brief digression into the company history of Orafo and Reflexite, as the microprismatic technology for reflective films was developed and established on the market by the founders of Reflexite. Reflexite (Orafol Americas Inc., Reflective Solutions Division) was integrated into Orafol Europe GmbH in August 2011.

In 1963, brothers Hugh and Bill Rowland acquired the rights to develop a new retroreflective production technique from the company Luce Reflexite.

In 1966, Bill Rowland designed the first prototype of a cube corner prism¹ from a sheet of a file folder. After many years of tinkering and trials and errors, the patent "Wide-angle retroreflector assembly and method of making same" was approved in the USA in August 1976 with the number 3,975,083. (Google Patents US3975083A)

¹ Source: traffic safety brochure: Reflective Solutions for Traffic Signs, Orafol Americas, p. 3

The "Brilliant Corners" sculpture depicts stacked cube corner prisms. The artist Robinson Fredenthal dedicated it to the founders of Reflexite, the brothers Hugh and Bill Rowland. In 2005, the sculpture was erected in front of the headquarters of Reflexite Corporation (now Orafol Americas Inc.) in Avon, Connecticut.

(Orafol Americas. Inc, Pictured: July 2019 © 2021 Google, Screenshot Google Streetview, April 2021)

The reflective film types from Orafol

ORALITE® is Orafol's brand for retroreflective materials. These are available as products based on glass beads or with microprismatic technology in all important grades of reflectivity.

Reflective materials can be used in many different ways and are used in a wide variety of areas - especially where better visibility has a benefit for the safety of everyone involved:

In road traffic, it is extremely important that traffic signs and information signs are easily recognisable (especially in poor light and visibility conditions due to weather conditions or at dusk and at night). Signs such as speed limits, motorway exits or danger zones can also be seen more quickly from a greater distance and drivers have more time to react.

Reflective materials are also used to mark objects (e.g. signs, containers, bollards) and danger zones in businesses and other locations, as well as on clothing for occupational safety. Another area of application for reflective films are

Differentiation of Orafol reflective films according to performance classes and application areas

The assortment of Orafol ORALITE reflective films includes various product lines that cover all reflection classes. There are products consisting of both microprismatic films and products made from glass bead-based materials.

The Orafol product lines Brilliant Grade, High Intensity Grade and Engineer Grade have been developed primarily for traffic sign applications and differ in their allocation to the three

Based on the performance classes, there are different areas of application:

RA1 films are mainly used for signs in areas with stationary traffic (e.g. no parking signs) and also for tourist information signs.

RA2 films are mainly used in moving traffic due to their higher reflective values (e.g. priority signs, speed limits).

RA3 films are used for signs in highly illuminated locations or where optimum visibility over long distances is particularly important (e.g. highway signs).

For more detailed information on the application areas, structure and performance classes of ORALITE reflective films, we recommend this overview of retroreflective materials from Orafol.

Designations of Orafol ORALITE films

In addition to the serial numbers, some Orafol reflective films are also categorised with letters that designate certain properties of the film. For example:

M after the serial number means it is a metallised film (e.g. ORALITE® 5931M)

RA means RapidAir® (RapidAir is a special technology that allows bubble-free and easy application of the film. e.g. ORALITE® 5600E RA)

T means translucent (translucent, e.g. ORALITE® 6910T)

The microprismatic Orafol ORALITE film types

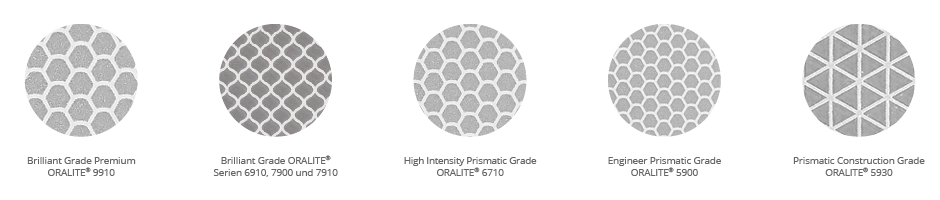

In addition to the serial numbers and letters in the product name, the cell structure, i.e. the pattern of the film surface, also provides an indication of the film type. For example:

Source: Orafol brochure Reflective Solutions, traffic signs and construction zones

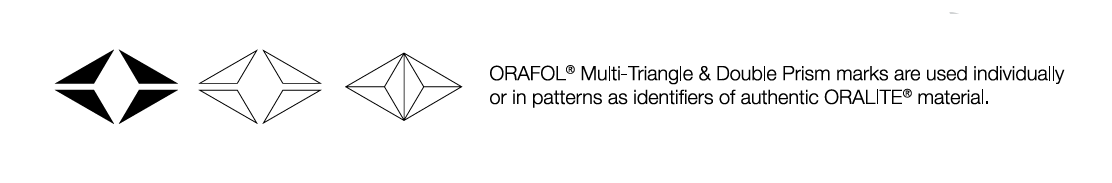

The illustration shows the different labelling of the prismatic ORALITE films. These serve to authenticate the genuineness of the material. Source: Screenshot from the brochure Reflective Solutions for Traffic Signs, Orafol Americas (January 2020, p. 2)

Further information on Orafol reflective films

For anyone interested in finding out more about Orafol reflective films, it is generally worth taking a look at the brochures. Complex topics are explained in detail and illustrated with pictures and graphics. Further information on the reflective films, especially technical details and instructions for use, can also be found in the data sheets for Orafol products. The data sheets are available in a separate tab on our product pages.

SYMBOLISM |

SYMBOLISM |  | Open PDF in separate Window

| Open PDF in separate Window